As the person responsible for operations, you are responsible for occupational safety and it is your duty to ensure the functionality and safety compliance of electrical equipment. DGUV Regulation 3 (formerly BGV A3) is essential in this regard. Important aspects of the DGUV V3 test:

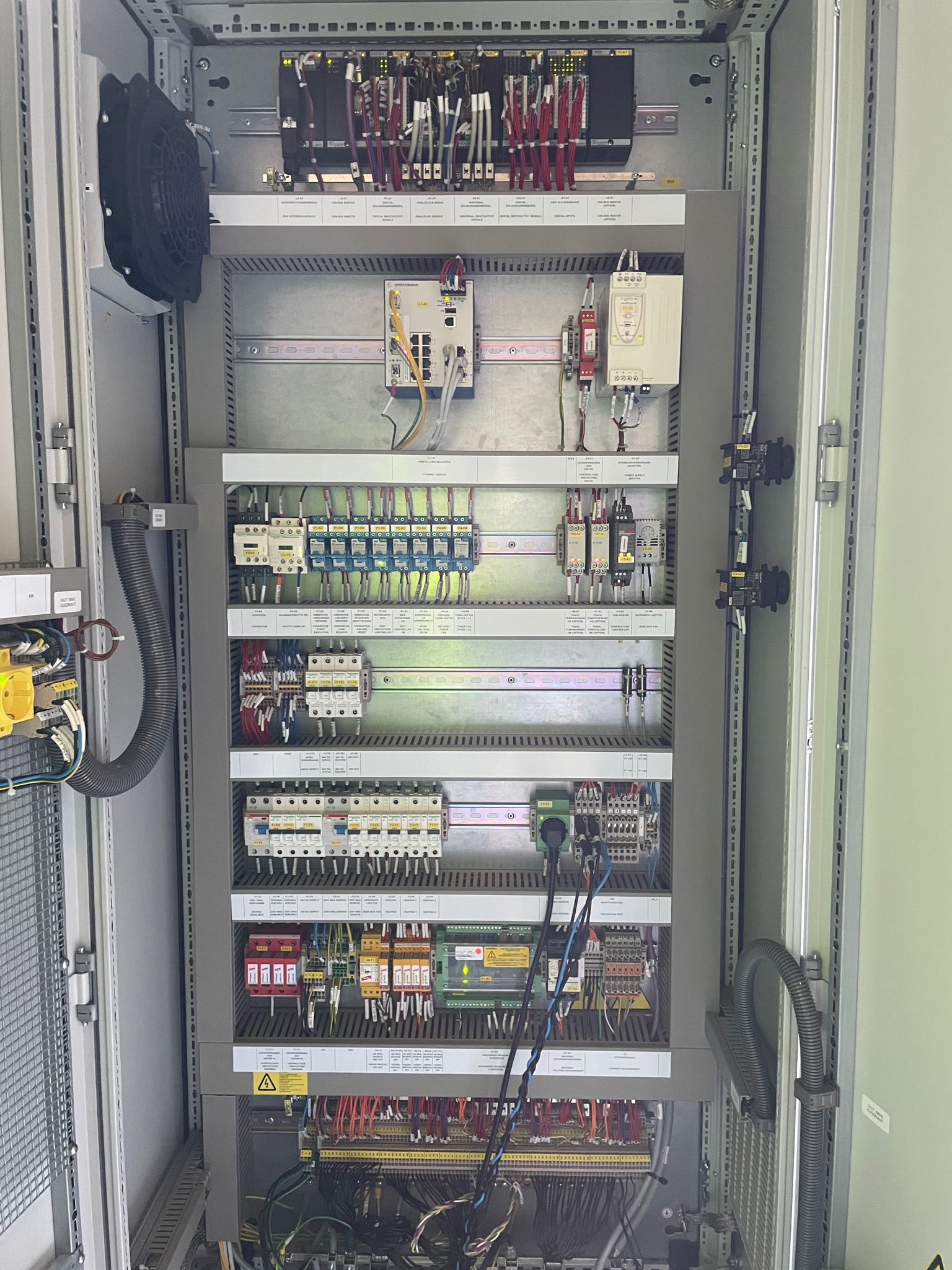

- Visual inspection: This initial inspection includes a visual inspection of electrical devices and systems to detect obvious defects such as damaged cables, faulty plugs or improper installations.

- Measurement check: Specialised personnel use special measuring instruments to check protective measures such as protective conductor resistance, insulation resistance and touch voltages.

- Functional check: Checking all safety and protective functions, including emergency stop switches and safety relays, to ensure they are working properly.

- Documentation: Complete recording of test results to fulfil legal requirements, identify recurring problems and plan future maintenance measures.

- Defect rectification and follow-up inspection: In the event of defects, immediate rectification and subsequent follow-up inspection are carried out to confirm the safety conformity of the repairs.

The DGUV V3 inspection is a continuous process that is repeated regularly to ensure safety in the workplace and reduce the risk of accidents and downtime.

Summary: Regular DGUV V3 inspections are crucial for a safe working environment and compliance with regulations. Rely on the expertise of morEnergy, whose qualifications and experience guarantee that they are carried out professionally. More information at DGUV V3 – the morEnergy method.